Some of

the major advantages of the Gen2 SuperControl:

|

|

- Overview

- More accurate motion

- Easier programming & program execution

- Communication

- Other features

| |

Advancing computer technology is driving the development of a new generation of CNC controls. Thermwood is a leader in implementing next generation control technology and has been granted more patents on CNC router technology than all other CNC router manufacturers in the world, combined. Advancing computer technology is driving the development of a new generation of CNC controls. Thermwood is a leader in implementing next generation control technology and has been granted more patents on CNC router technology than all other CNC router manufacturers in the world, combined.

CNC router manufacturers have reacted in two ways to changes in control technology. One group attempts to save money by offering limited first generation controls. First generation controls simply play back CNC programs, much like a player piano. Thermwood has chosen another path, incorporating advanced next generation features into its CNC control using the most advanced, modern technology available.

You might think the first approach results in lower cost systems that are easier to use, but the exact opposite is true. Operating a CNC machine in the real world involves more than just running a program. It requires a multitude of disciplines including, among others, tooling, maintenance, configuration, error handling, adjustment and support. First generation controls don’t do any of this so you must handle it all yourself. This requires a high level of skill and training plus a lot of downtime as you fumble with problems. Next generation controls have systems for quickly and easily handling all this, many times automatically in the background. First generation controls are less productive, requiring more effort, more time and more training generally resulting in more downtime, missed schedules and more frustration. All these problems in an effort to save a little money and yet the difference in cost is insignificant compared to the cost of a typical CNC router.

Actually, you can argue that Thermwood’s next generation control is lower cost than limited first generation controls. The lower cost comes from the fact that next generation controls perform functions internally that require separate software packages and additional steps for first generation controls. The additional software and less efficient functioning of the first generation approach are substantially higher cost than the advanced processors needed for next generation features.

When you move into more advanced applications, machining complex CAD generated surfaces or three-dimensional volumetric compensation of large envelope machines, no other control can match the Gen2 SuperControl. It easily executes multi-gigabyte programs that choke other controls, creating complex surfaces to unheard of accuracies. There are even higher level functions reserved for highly experienced programmers and research labs to handle the most sophisticated applications. Whether you are making simple cabinets or the most sophisticated scientific project, no CNC control will outperform Thermwood’s Gen2 SuperControl.

|

| |

More

complex motion algorithms - The high speed processors allow

more complex motion calculations resulting in smoother machine

motions and faster speeds More

complex motion algorithms - The high speed processors allow

more complex motion calculations resulting in smoother machine

motions and faster speeds

|

| |

|

| |

Three-dimensional

axis compensation Three-dimensional

axis compensation - Good

quality first generation controls provide for lead screw

compensation, that is, they use a table to compensate

for any position inaccuracy along an axis. The table

is created by measuring precise actual position along

an axis using a laser. The only problem is that moving

along one axis may cause inaccuracies on the other two

perpendicular axes. Any slight mechanical variation or

natural flex can cause these movements and there is no

way to eliminate them through mechanics or structure.

First generation compensation only corrects pitch error

on each axis, ignoring any effect on the perpendicular

axes. Next generation controls compensate all three axes

at every position within the working envelope. Every

inaccuracy or misalignment, regardless of its source,

is automatically corrected.

|

| |

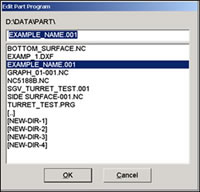

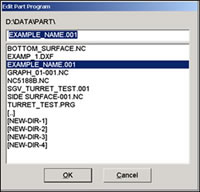

Control

can accept raw design files in addition to CNC programs Control

can accept raw design files in addition to CNC programs - First

generation controls are primarily playback devices, much

like a player piano. They require that the programmer not

only design the part but also perform a series of additional

functions including CAM, nesting, and post processing in

order to generate a precisely formatted program that the

control can execute. Next generation controls such as Thermwood’s

Gen2 SuperControl can, in addition to standard CNC programs,

also accept raw design files directly from design software

without the additional processing. It automatically performs

any program preparation necessary to machine the part.

|

| |

|

| |

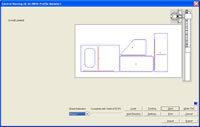

Control is directly compatible with virtually all design software - DXF files from any CAD or design software can be sent directly to a Gen2 SuperControl - Thermwood’s Gen2 SuperControl accepts data base file output from all major cabinet design software packages, then nests the parts and creates a program to run them. It can also accept and include in the nest DXF files from any CAD or design software that can output standard layer names. In fact, the control can accept input from multiple design packages and multiple DXF files and combine them all into a single job, right at the control. Control is directly compatible with virtually all design software - DXF files from any CAD or design software can be sent directly to a Gen2 SuperControl - Thermwood’s Gen2 SuperControl accepts data base file output from all major cabinet design software packages, then nests the parts and creates a program to run them. It can also accept and include in the nest DXF files from any CAD or design software that can output standard layer names. In fact, the control can accept input from multiple design packages and multiple DXF files and combine them all into a single job, right at the control. |

| |

|

| |

Combine

files from multiple software sources in a nest Combine

files from multiple software sources in a nest - The control creates nests of parts internally and can

combine parts from multiple sources in the same nest. |

| |

|

| |

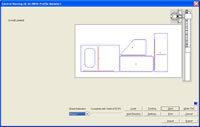

A

single job file can contain hundreds of parts rather than

requiring hundreds of separate CNC programs for a job A

single job file can contain hundreds of parts rather than

requiring hundreds of separate CNC programs for a job -

Including all the parts for a job in a single file can

dramatically reduce file handling and improve productivity

of the machine. The control nests the

parts on the appropriate material, tells the operator how

many sheets of material are needed for the job and tells

him what material to load. In fact, it guides him through

the entire process, step by step. This file also contains

information for machining the back or flip side of certain

parts. It prints a label for each part. Parts that require

flip operations have a bar code on the label. When the

operator scans the bar code, it identifies the part to

the control which automatically retrieves the correct program.

From the operator’s

standpoint the whole process is simple, load one file and

follow instructions. In a first generation control, the

CNC programs are developed outside the control, so there

is a program file for each sheet of material in the job

and yet another program file for each flip operation. These

files are normally processed into individual CNC programs.

A single job may require a hundred files or more that must

be sent individually to the machine. Some really limited

controls may only allow one, or maybe a couple of programs

to be loaded at a time. An operator then needs to

sort through, identify, handle and load hundreds of files

each day. This takes time and reduces productivity of a

major investment, the CNC router. Also, this approach is

more prone to error.

|

| |

|

| |

React

to problems at the machine - React

to problems at the machine - For

example, if you have a damaged sheet or a partial sheet

of material, it is easy to tell the control what you

have and it will nest on it. If the partial sheet is

from a previous job, it is not even necessary to provide

a description to the control. The control prints a bar

code label for any material left from a job and all you

need to do is scan that label. Theoretically this is

possible with a first generation approach but from a

practical standpoint, most times you don’t know

exactly what you have until you are ready to run the

job. Changes are easy at the control with little delay

to the job but that’s usually not a good time to

stop everything, go back to the office to re-program.

|

| |

|

| |

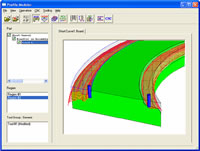

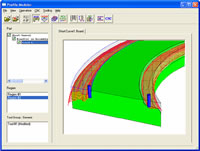

Create

modeling program to produce almost any profile

without custom tooling - When

you have a design with a profile edge, there are two

ways to cut the profile.The most common way is to have

a cutting tool made with the desired profile. A second,

less known method is to model the profile. Modeling

is a technique commonly used to make prototypes or

patterns from CAD designs. It uses a series of standard

tools. The process begins by moving a ball nose tool

back and forth over the surface, incrementing a small

distance each pass. This creates the base surface of

the part. Then a second and perhaps third tool are

used which machines away those areas that the first

tool could not reach. With the higher speeds of today’s

CNC routers, modeling is practical for short run production

parts but does require a modeling program. Most CAD

systems can create modeling programs but seldom are

used for this purpose. Thermwood’s Gen 2 SuperControl

has the ability to create these modeling programs,

automatically right in the control. If you send a part

with a profile edge to a Gen 2 control, it asks if

you have a tool for the profile. If you say no, it

automatically creates a modeling program to machine

the edge. This simple feature can be incredibly useful.

It can be used to machine custom profiles on parts

or machine moldings, even large complex or curved moldings

without special tooling. Create

modeling program to produce almost any profile

without custom tooling - When

you have a design with a profile edge, there are two

ways to cut the profile.The most common way is to have

a cutting tool made with the desired profile. A second,

less known method is to model the profile. Modeling

is a technique commonly used to make prototypes or

patterns from CAD designs. It uses a series of standard

tools. The process begins by moving a ball nose tool

back and forth over the surface, incrementing a small

distance each pass. This creates the base surface of

the part. Then a second and perhaps third tool are

used which machines away those areas that the first

tool could not reach. With the higher speeds of today’s

CNC routers, modeling is practical for short run production

parts but does require a modeling program. Most CAD

systems can create modeling programs but seldom are

used for this purpose. Thermwood’s Gen 2 SuperControl

has the ability to create these modeling programs,

automatically right in the control. If you send a part

with a profile edge to a Gen 2 control, it asks if

you have a tool for the profile. If you say no, it

automatically creates a modeling program to machine

the edge. This simple feature can be incredibly useful.

It can be used to machine custom profiles on parts

or machine moldings, even large complex or curved moldings

without special tooling.

|

| |

|

| |

Design

files can be exchanged between machines without post

processing – Just

like fingerprints, no two CNC machines are the same.

Sometimes differences are major, like different table

sizes. Sometimes differences are subtle, like different

head spacing. Regardless, no two machines are exactly

the same so the CNC program needs to be tailored to

the particular machine it will be run on. If you want

to run the exact same part on different machines using

a first generation control, you need to create a different

program tailored to EACH machine. With first generation

controls, you cannot freely exchange programs between

machines. Next generation controls, however, accept

design files and automatically tailor the program to

produce the correct part. You can freely exchange these

files between machines with next generation controls

regardless of the physical differences in the machine.

This is the basis for an entire Production Sharing

program under which Thermwood machine owners make parts

for other shops. Design

files can be exchanged between machines without post

processing – Just

like fingerprints, no two CNC machines are the same.

Sometimes differences are major, like different table

sizes. Sometimes differences are subtle, like different

head spacing. Regardless, no two machines are exactly

the same so the CNC program needs to be tailored to

the particular machine it will be run on. If you want

to run the exact same part on different machines using

a first generation control, you need to create a different

program tailored to EACH machine. With first generation

controls, you cannot freely exchange programs between

machines. Next generation controls, however, accept

design files and automatically tailor the program to

produce the correct part. You can freely exchange these

files between machines with next generation controls

regardless of the physical differences in the machine.

This is the basis for an entire Production Sharing

program under which Thermwood machine owners make parts

for other shops.

|

| |

|

| |

Run

panel saw programs Run

panel saw programs - Thermwood’s

control accepts either Excel or CPOUT files commonly

used to send size information to a panel saw optimizer.

It then nests the panels and cuts them. Since panels

do not need to be lined up along common cut lines, as

they do in a panel saw, they can be true shape nested,

often resulting in better yield. If you just want rectangular

panels, you can also just type a list of sizes at the

control and it will nest and cut them.

|

| |

|

| |

Produce

cabinet and furniture doors - The

Gen2 SuperControl has the ability to take door definition

files from eCabinet Systems and create machine programs

to make either MDF or traditional solid wood raised panel

doors. Produce

cabinet and furniture doors - The

Gen2 SuperControl has the ability to take door definition

files from eCabinet Systems and create machine programs

to make either MDF or traditional solid wood raised panel

doors. |

| |

Reconfigure

control operation for special applications - Thermwood’s

Gen2 SuperControl includes the ability to read imbedded

Advanced Function Language commands in the CNC program

and reconfigure control operation based on those commands.

The Advanced Function Language is a programming language,

similar to Microsoft Basic that can be included in a CNC

program to make it into an intelligent computer program,

capable of reacting to its environment or operator input.

This feature, which is intended for sophisticated users,

will allow the control to address complex or sophisticated

applications for which the control was not originally intended. Reconfigure

control operation for special applications - Thermwood’s

Gen2 SuperControl includes the ability to read imbedded

Advanced Function Language commands in the CNC program

and reconfigure control operation based on those commands.

The Advanced Function Language is a programming language,

similar to Microsoft Basic that can be included in a CNC

program to make it into an intelligent computer program,

capable of reacting to its environment or operator input.

This feature, which is intended for sophisticated users,

will allow the control to address complex or sophisticated

applications for which the control was not originally intended.

|

Machine

communication to the operator Machine

communication to the operator |

| |

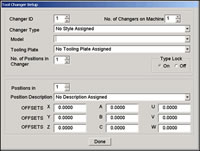

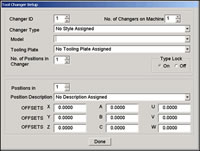

Tool

Management - The

Gen2 SuperControl has a tool management system used to

define and manage tools. With the advent of automatic

tool changers and random use of tools, this makes management

of tooling easier and tracks tool use, informing the

operator when tool life has expired for a particular

tool. It can even automatically switch to a back-up tool

when life expires. Tool

Management - The

Gen2 SuperControl has a tool management system used to

define and manage tools. With the advent of automatic

tool changers and random use of tools, this makes management

of tooling easier and tracks tool use, informing the

operator when tool life has expired for a particular

tool. It can even automatically switch to a back-up tool

when life expires. |

| |

|

| |

Maintenance

Tracking - The

Gen2 SuperControl tracks routine maintenance, alerting

the operator when maintenance such as lubrication or

filter cleaning is required. Maintenance

Tracking - The

Gen2 SuperControl tracks routine maintenance, alerting

the operator when maintenance such as lubrication or

filter cleaning is required.

|

| |

|

| |

Error

Reporting - When

an error occurs, the control displays a diagram of the

machine pointing out possible causes for the error and

suggesting solutions. Error

Reporting - When

an error occurs, the control displays a diagram of the

machine pointing out possible causes for the error and

suggesting solutions. |

| |

|

| |

Electronic

searchable operator’s manual - The

Gen2 SuperControl includes a complete operator’s

manual that can be displayed on the screen including

the ability to search for words or phrases. Electronic

searchable operator’s manual - The

Gen2 SuperControl includes a complete operator’s

manual that can be displayed on the screen including

the ability to search for words or phrases. |

| |

|

| |

Maintenance

Videos - Maintenance

Videos - The Gen2 SuperControl

will display videos that detail common maintenance

adjustment or repair procedures, allowing users to

perform many of these functions without outside technical

assistance.

|

| |

|

| |

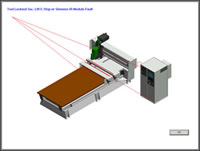

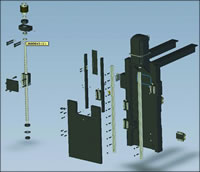

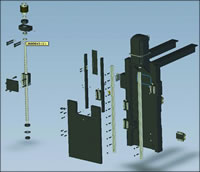

Dynamic

exploded assembly drawings Dynamic

exploded assembly drawings

- The

Gen2 SuperControl can display three-dimensional images

of all machine assemblies which can be rotated and

exploded on the screen. This shows customer maintenance

people the assembly sequence for all components and,

by placing the cursor over any part it displays the

part number making it easy to order replacement parts.

|

| |

Job

Guide - Job

Guide - When a job containing

a large number of parts is sent to the Gen2 SuperControl,

it nests the parts, tells the operator the number of

sheets of each material needed for the job and guides

him through the job step by step.

|

|

Operator

communication to technical help and resources Operator

communication to technical help and resources

|

| |

Direct

audio/visual/data link to Thermwood technical assistance - Direct

audio/visual/data link to Thermwood technical assistance - The

Gen2 SuperControl can quickly connect to Thermwood technical

service through a Virtual Service communication link.

This audio visual link allows the machine operator to

see and hear the Thermwood technician and allows the

Thermwood technician to see and hear the machine operator.

The link also provides in-depth data sharing allowing

the following:

Complex

data and diagnostics – Using

the Virtual Service communications link allows a Thermwood

technician to access all the data, error logs and configuration

files that he could access if he were actually at the

machine. Complex

data and diagnostics – Using

the Virtual Service communications link allows a Thermwood

technician to access all the data, error logs and configuration

files that he could access if he were actually at the

machine.

Remote

machine configuration and tuning – Remote

machine configuration and tuning – Using

the Virtual Service communication link the Thermwood

technician can evaluate machine performance, then

adjust and reconfigure the machine as required, all

remotely.

Program

debugging assistance – Program

debugging assistance – Most

machine problems are caused by programming errors.

The Virtual Service communication link allows a

Thermwood technician to review, and if necessary

modify programs working directly with the customer.

Purchase

tooling or spare parts – Purchase

tooling or spare parts – Using

the Virtual service communication link a customer

can purchase spare or replacement part right through

the Gen2 SuperControl.

|

| |

| |

Hand

Held Programmer Hand

Held Programmer - Thermwood offers a hand held

programming device that is used to move the machine around.

It is used to quickly, easily and intuitively create

programs without having to deal with cryptic CNC code.

This is a great tool for those not familiar with CNC |

| |

|

| |

|

| |

|

| |

Depth

oscillation increases tool life - Depth

oscillation increases tool life - Certain

materials such as high pressure laminates and certain

types of plywood with abrasive adhesive between layers

will quickly dull tooling at the point or points where

the tool contacts the abrasive layer or layers. The

Gen2 SuperControl has a feature which oscillates the

tool up and down as it cuts to move this abrasive contact

point over a larger area of the tool increasing tool

life dramatically.

|

| |

|

| |

Full

color display Full

color display - A full size, full color flat

panel display makes information easier to read and

understand, allows display of more information, including

graphics and pictures and generally makes the control

simpler and easier to use. |

| |

|

| |

Huge

program storage Huge

program storage – The Gen2 SuperControl

has, as standard, a 120 Gigabyte hard disk drive allowing

storage at the control of tens or hundreds of thousands

of part programs and allows the storage of very large

programs such as those used for carving. The control

can easily, efficiently and without pausing, process

programs that are many gigabytes in size, and can process

blocks of data at unequaled speeds, resulting in faster

execution of these types of programs.

|

| |

|

| |

Sealed

air-conditioned cabinet - Sealed

air-conditioned cabinet - Thermwood

encloses its controls, including power supplies and servo

drives, in a sealed, air conditioned cabinet keeping

them cool, free from contamination which substantially

improves reliability. |

| |

|

| |

Proper

wire and component labeling Proper

wire and component labeling - Thermwood uses

professional wiring practices in its control, labels

and color codes all wires, labels major components

inside the control cabinet to make finding them easy

for service (changing a fuse for example), and supplies

complete blueprints of wiring inside the control.

|

| |

|

| |

Easy

update and upgrade – Advanced Support Program Easy

update and upgrade – Advanced Support Program -

Since Thermwood designs its own control, it can tailor

new features so that they can be easily added to existing

controls. This keeps you competitive as control technology

advances. Thermwood offers an Advanced Support Program

which provides automatic software updates each year,

continuing Virtual Service and discounts on hardware

upgrades and other service products. |

| |

|

| |

Single

source responsibility - Thermwood builds both

the machine and the control. Should you have a problem

it is Thermwood and no one else responsible for fixing

it. Single

source responsibility - Thermwood builds both

the machine and the control. Should you have a problem

it is Thermwood and no one else responsible for fixing

it.

Upgrade

Existing Controls to Next Generation

Most existing Thermwood CNC controls can be upgraded

to the new Gen2 SuperControl. This allows existing Thermwood

CNC routers to benefit from advancing next generation

technology at a relatively low cost without requiring

that the entire control be replaced. 91000 SuperControls

and early Gen2 SuperControls can generally be updated

rather quickly and easily. Older controls, even those

using DC servo drives can also be updated to a full Gen2

SuperControl with the addition of certain electronic

hardware. This upgrade does not generally require that

the servo motors be replaced resulting in much lower

upgrade cost.

Please check with Thermwood’s Technical Service for more information on upgrading your existing Thermwood

machine.

|

|

Toggle

program display between EIA and English -

You can toggle the program display on all Thermwood

controls from the cryptic “M” and “G” code,

EIA designators to an English language description

of each line in the program. This greatly simplifies

operation and learning for people not familiar with

CNC code.

Toggle

program display between EIA and English -

You can toggle the program display on all Thermwood

controls from the cryptic “M” and “G” code,

EIA designators to an English language description

of each line in the program. This greatly simplifies

operation and learning for people not familiar with

CNC code. Huge

program storage – The Gen2 SuperControl

has, as standard, a 120 Gigabyte hard disk drive allowing

storage at the control of tens or hundreds of thousands

of part programs and allows the storage of very large

programs such as those used for carving. The control

can easily, efficiently and without pausing, process

programs that are many gigabytes in size, and can process

blocks of data at unequaled speeds, resulting in faster

execution of these types of programs.

Huge

program storage – The Gen2 SuperControl

has, as standard, a 120 Gigabyte hard disk drive allowing

storage at the control of tens or hundreds of thousands

of part programs and allows the storage of very large

programs such as those used for carving. The control

can easily, efficiently and without pausing, process

programs that are many gigabytes in size, and can process

blocks of data at unequaled speeds, resulting in faster

execution of these types of programs.

Easy

update and upgrade – Advanced Support Program -

Since Thermwood designs its own control, it can tailor

new features so that they can be easily added to existing

controls. This keeps you competitive as control technology

advances. Thermwood offers an Advanced Support Program

which provides automatic software updates each year,

continuing Virtual Service and discounts on hardware

upgrades and other service products.

Easy

update and upgrade – Advanced Support Program -

Since Thermwood designs its own control, it can tailor

new features so that they can be easily added to existing

controls. This keeps you competitive as control technology

advances. Thermwood offers an Advanced Support Program

which provides automatic software updates each year,

continuing Virtual Service and discounts on hardware

upgrades and other service products.