LSAM > Printing Software

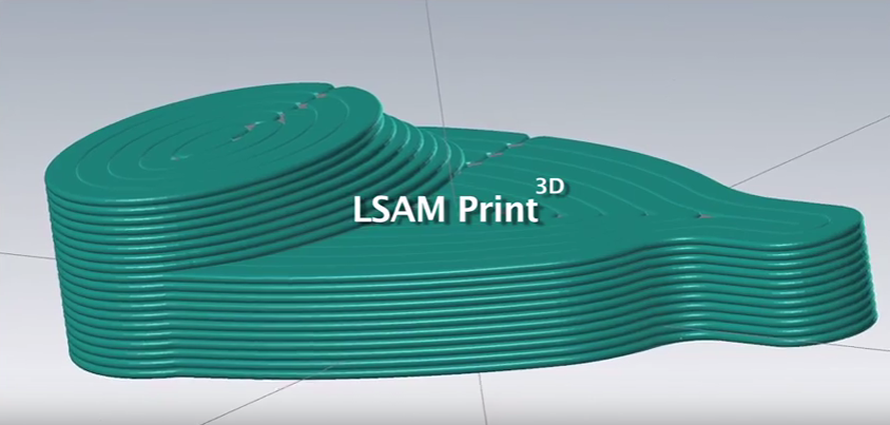

Thermwood’s LSAM LSAM Print 3Dsoftware utility

LSAM Printing Software

Most 3D printing software is designed for small machines that output a small bead in thin layers to print parts to the final net size and shape. Thermwood’s approach is fundamentally different, so existing software doesn’t work. LSAM machines use a “near-net-shape” approach where parts are printed layer by layer to a size that is slightly larger than needed and then the printed part is accurately trimmed to the final net size and shape using a CNC router. The software must not only accommodate relatively large bead sizes, whose size can be dynamically changed by programming but must also print to a size which provides sufficient trim stock for the final trimming process.

To address this, Thermwood offers an additive manufacturing software utility for its LSAM machines called LSAM Print 3D which operates within Mastercam, featuring multiple printing options and techniques which are essential for “near-net-shape” additive printing of large components.

To create a print program using LSAM Print 3D, an initial 3D computer model is generated using a CAD system.

The 3D computer model, in an industry standard solid, surface or mesh file format, is loaded into Mastercam software and Thermwood’s LSAM Print 3D utility is used to create a print model and generate the CNC machine code needed to actually print the part.

Then a CNC trim program is generated to trim the part to size.

Certain unique print patterns and features, beneficial for making masters, molds, and tooling, have been integrated into the LSAM Print 3D software utility. These include the ability to vary bead width during printing, the ability to print asymmetrical wall thickness with some walls thicker than others and the ability to vary wall thickness from layer to layer.

By incorporating the printing software within Mastercam, a single software can be used to create programs for both printing and subsequent trimming. If desired, this approach easily integrates with existing CAD/CAM systems for everything but the print programming function.