LSAM > Specifications

Printing and trimming on the same machine.

LSAM Specifications:

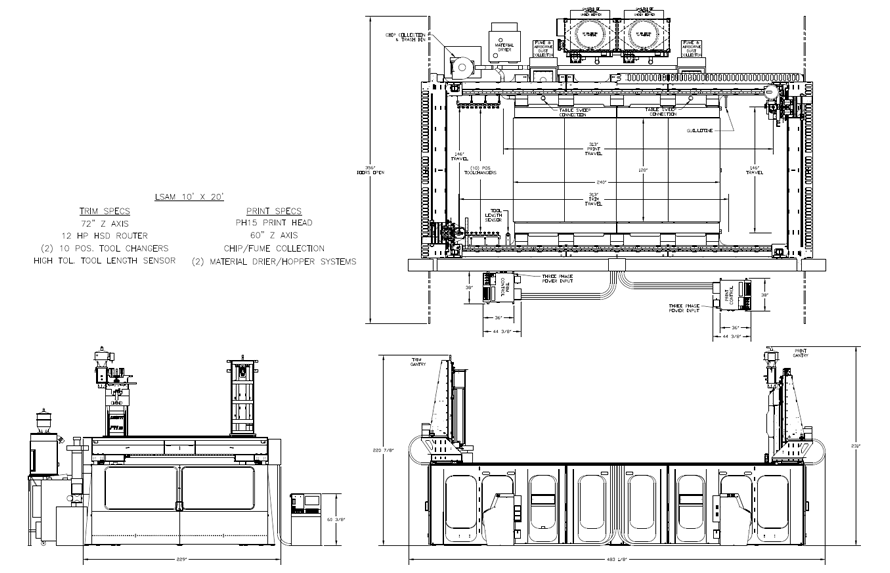

Dimensions (click for larger size):

Configuration:

High wall, dual gantry operating over a fixed work table

Construction:

Rigid engineered steel structure using tabbed steel plate and an aluminum jig plate table top

Envelope Size:

Printing – 10ft wide, 5ft high up to 100ft long

Trimming – 10ft wide, 6ft high and same length as the printing envelope

Simultaneous Operation:

Both the Print Gantry and the Trim Gantry can operate simultaneously, printing on one side of the table while trimming on the other side. An automatic software “Reservation” system allows each gantry to reserve a portion of the table for the program it is currently running, maximizing flexibility while eliminating the possibility of the gantries contacting each other.

Print Head configuration:

Vertically mounted servo controlled advanced design print head melts thermoplastic material and precisely meters it through a heated print nozzle where a servo controlled wheel compresses and fuses the melted material to the structure being printed

Available Melt Cores:

-40mm – a patented 40mm high speed extrusion screw coupled to a corresponding melt pump and deposition head. This standard configuration processes over 200 pounds of material an hour, depending on the specific material and is suitable for parts that have a print layer lap length of up to 200 feet while printing a standard bead that is .200 inch thick and .830 inch wide.

-60mm –can process 50% more than the 40mm Melt Core

-70mm – operated at rates of over 500 pounds per hour, which Thermwood expects to increase

Notable Features:

- Advanced design high throughput print heads

- Compression wheel with automatic tangential tracking of machine motion

- Dynamic print bead dimension control

- Automatic coordination of print head output to machine speed

- Dual hopper polymer drier can simultaneously dry two different materials

- Each gantry has its own free standing CNC control

- Siemens Intelligent Servo Drives throughout

- Siemens print head temperature and pressure controls

- Built in machine routines for special functions such as print head startup, shutdown and Hot-Hold idle mode

Request More Information on LSAM