New Low-Cost, High Performance CabinetShop 43 5×10 CNC Router!

We are pleased to announce our latest machine, the CabinetShop 43! This low-cost, high-performance 5×10 table CNC Router is perfect for making nested based cabinets, closets, furniture and upholstered frames.

Please click here for more information

Thermwood announces QuickCut Cabinet and Closet System

Thermwood Corporation, a leading manufacturer of CNC routers has announced a new, simplified approach to nested based production of cabinets and closets that does not require separate cabinet design software. This new approach, called “QuickCut”, is done entirely at the CNC machine.

Thermwood Corporation, a leading manufacturer of CNC routers has announced a new, simplified approach to nested based production of cabinets and closets that does not require separate cabinet design software. This new approach, called “QuickCut”, is done entirely at the CNC machine.

The operator, working at the machine control, simply selects and resizes cabinets and closets from a built-in library and runs them. This entire process happens at the machine. The process is simple enough that virtually anyone can run it with minimal instruction.

Libraries will be installed with QuickCut and more can be downloaded for free from www.ecabinetsystems.com. Libraries can also be modified or extended through our programming service as well as using the free eCabinet Systems software.

“For the first time you can operate a CNC router without extensive training or technical skill”, says Thermwood’s Vice-President of Marketing Jason Susnjara. “This approach allows cabinetmakers to focus on making cabinets using an amazing new tool that’s really easy to use”.

Operating a CNC router usually requires specialized knowledge which limits its use to specially trained employees. Thermwood used the technical power in its Gen2 SuperControl to totally automate virtually every task, then created a simple user interface, resulting in a system that almost anyone can use without extensive training.

The QuickCut feature targets smaller, less technical shops but can also be used by larger companies to make virtually any part or product in their product line any time they want. A library of parts can be stored on a network drive. At that point, almost anyone can walk up to any QuickCut machine and make any part. It’s that easy. By storing files in a central location, management has complete control of anything that is made, anywhere in the factory.

“This new interface takes what has been a confusing area for non-technical users and makes it almost as easy as using a copy machine”, states Thermwood’s President, David Hildenbrand. “We believe it will fundamentally change how cabinets, closets and perhaps many other products, are made”.

All nested based systems from Thermwood are QuickCut compatible and Gen2 systems operating in the field can be retrofitted to make them QuickCut compatible.

For more information on this exciting new development, please visit our QuickCut area of the website.

Thermwood announces a simpler, easy way to make cabinets, closets or any other nested based product.

Thermwood has developed a new system for nested based manufacturing of cabinets, closets and other products made from sheet stock. Thermwood’s unique approach results in systems that are highly productive, extremely easy to use, yet are among the lowest cost.

Thermwood’s advanced Gen2 SuperControl is the element that separates Thermwood’s nested based systems from every other. It automatically performs complex technical functions that otherwise require technical skill, extensive training and programming time. This makes Thermwood’s nested based systems the fastest, simplest and easiest to use. The system functions at three levels:

For more information on this exciting new development, please visit our nested based manufacturing area.

Thermwood and 20-20 Technologies Offer Comprehensive New Cabinet Manufacturing Solution

20-20 Technologies and Thermwood Corporation have joined together to offer a smoothly integrated, highly productive manufacturing system for cabinet manufacturers.

"We are very excited about this new partnership," said Ken Susnjara, CEO of Thermwood. "This represents a truly comprehensive approach from design and retail all the way through manufacturing, all working together smoothly and seamlessly. It combines the best technology of both Companies to create an industry-leading offering."

The data process starts with the design. Over 50,000 dealers use 20-20 Design or ShopWare CAD to layout and sell projects. To machine a job, an output file from 20-20 software is sent directly to a Thermwood CNC router and the advanced CNC control on the Thermwood system automatically performs all required CAD functions, nests the parts, prints nest diagrams and labels and runs the job directly from full sheets of material. For even higher production volume, rectangular panels without additional machining are sent to an optimized panel saw, and only parts that require CNC machining are sent to the router. This not only increases overall production capacity, but represents an increase in productivity as well.

"The advantages to using nested based techniques for machining instead of cutting all panels on a saw and then processing machined parts one at a time on a machining center are significant," said Craig Yamauchi, Executive Vice-President of Manufacturing & Residential Solutions of 20-20 Technologies. "Labor requirements are less and productivity is higher, sometimes substantially higher."

20-20 welcomes the opportunity to demonstrate the ease of use and high functionality delivered by this partnership for shops seeking best practices and robust integration at this year's AWFS show in July. 20-20 representatives will be on site to show how you can go from the showroom to the shipping dock with greater sales tools, lower costs, fewer errors and increased ROI.

Thermwood Links eCabinet Systems to ShopBot

We have developed a ShopBot Link that will allow CNC output from eCabinet Systems software to operate ShopBot CNC routers. The ShopBot Link software program, accepts a .twd output file from eCabinet Systems, nests the parts and creates properly formatted files for the ShopBot control.

The new program is the result of a joint effort between Thermwood and ShopBot to expand the use of CNC in the cabinet and custom furniture business. The availability of highly capable but free design software that can output to entry level CNC routers should speed the acceptance of this technology in the marketplace and should ultimately expand the market for everyone.

We have also restructured the eCabinet Systems program and added free access to a large collection of cabinet, furniture, closet and carving libraries. These designs, including the carvings, can now be machined on ShopBot CNC routers. For additional information see http://www.ecabinetsystems.com.

Thermwood Links eCabinet Systems Software to Panel Saws

We have created a software module it calls the "Code Splitter" that takes the CNC output file from eCabinet Systems design software and separates out any rectangular panels which don't require additional machining and sends them to an optimized panel saw. The result is a system that is ideal for higher volume cabinet manufacturers, combining the volume production of the 32mm Euro approach with the higher efficiency of nested based manufacturing.

With this approach, only panels that don't require additional machining are run through the panel saw, saving time and material handling between the panel saw and machining center. The parts that require CNC machining are nested on full sheets, a process that is more productive and offers higher throughput than adjusting pods, loading and unloading parts one at a time on a machining center. The result is a system that is more productive offering higher production volume than either of the two more traditional approaches alone.

This system requires the use of eCabinet Systems software. The software is free and incorporating it into most operations is relatively simple. Existing design or marketing software is left intact and can continue to be used as today. The cabinet libraries are reproduced in eCabinet Systems which can be done by each company or can be done by Thermwood through a design program it offers. After orders are received, they are batch entered into eCabinet Systems and output to the appropriate machines, a quick and easy process. Using this approach, higher manufacturing productivity can be achieved without major disruptions

The "Code Splitter" software is configured for popular saws and optimizers but offers a highly flexible output that can be configured for virtually any system. For more information see http://www.ecabinetsystems.com

Thermwood Restructures the eCabinet Systems Program

We have restructured the eCabinet Systems program to broaden its appeal and make the software easier to learn.

We have restructured the eCabinet Systems program to broaden its appeal and make the software easier to learn.

In addition to continuing to offer the design software free to manufacturers and professional cabinet builders, a major new feature of the restructuring is free access to a collection of cabinet, furniture, closet and carving libraries. These libraries mean that most users can just download and build without having to first learn the software and create their own libraries. We also offer a program to modify these libraries or create all new libraries for individual customers if they want.

For those that want an in-depth understanding of the software we have developed an extensive web based training program modeled after our successful week long software class. Access to the program is on a subscription basis and we plan a continuous program of additions and enhancements.

Another major departure from the past is the ability to output code to machines other than Thermwood. Two interface modules have been announced; one to ShopBot CNC routers and one that sends rectangular parts from a job to an optimized panel saw and sends cut-to-length parts to a TigerStop. Thermwood believes these two additions will expand the program by allowing smaller shops to begin using low cost CNC routers and supporting higher volume, panel saw production for larger shops. We have also established an all new eCabinet Systems web site, http://www.ecabinetsystems.com to support the restructured program.

Color-Coded Labels

A typical nested based job consists of perhaps hundreds of parts representing dozens of cabinets, all intertwined in a series of nests. The first task is to separate the parts into individual cabinets.

This is normally done by placing labels on each part. Each label has a text statement with the cabinet name. Simply read the name and sort the cabinets by those names.

While this sounds simple, it actually takes quite some time. You must read each label (even this is a problem if your worker can’t read or speak English). Then you must read the labels on the stacks of cabinets you are sorting to find the matching name. This reading takes time and cabinets have similar names so mistakes are pretty easy to make.

Thermwood’s new patent pending approach prints a color bar on each label with a different color for each cabinet. Put the red parts with the red parts and the green parts with the green parts. This simple idea allows you to sort cabinet two to three times faster. This offers a significant productivity improvement.

|

|

|

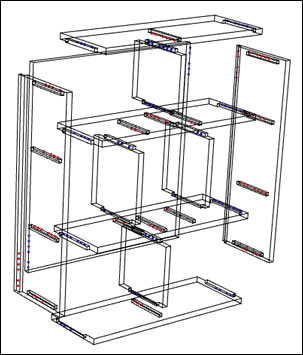

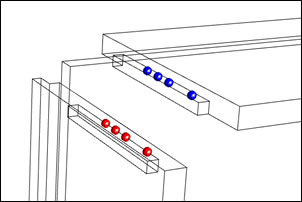

Assembly Marks

|

Designed with Assembly Marks in eCabinet Systems |

|

|

|

Another even more significant productivity improvement involves actually putting the cabinets together. Simple cabinets are not all that difficult to assemble so major productivity improvement is not likely but as the cabinet design becomes more complex, major productivity improvements are possible. Once fixed partitions, shelves or other features are added to a cabinet, determining exactly how to assemble the parts can become difficult. Generally you must create and print assembly drawings and even with these drawings, the process of sorting out the structure can take significant time.

Thermwood’s approach (also patent pending) machines assembly marks into each joint which define which part mates with which part. These marks are hidden once the parts are assembled. Assembly drawings aren’t needed and in fact, totally non-skilled workers can easily and quickly assemble even the most complex cabinets. One shop owner asked his cleanup man to assemble a cabinet as a test. This totally unskilled “cabinetmaker” assembled the cabinet quickly and accurately with no drawings or instructions. For most jobs this represents a productivity improvement that could rival that realized for the machining process itself.

So when looking for productivity improvements from CNC routers look to the supporting or peripheral processes and the impact you could have on downstream processes. Right now, today, that’s where the greatest return can be found.

|

Designed with Assembly Marks in eCabinet Systems |

|

|

|

Note: Thermwood has applied for patent protection on the assembly marks, color and symbol coding of labels and the supporting software for these. They will provide a royalty free license under any patents issued for any parts made on a Thermwood CNC router and has offered a royalty free license to software developers for file output to Thermwood CNC routers.

Assembly Marks in Action (click on thumbnails to see larger views) |

|

|

|

|