HARDWOODS - SOFTWOODS - FIBERBOARD (MDF) - PARTICLEBOARD - PLASTICS - ALUMINUM

MULTIPURPOSE 42

Moving table, fixed gantry, CNC router primarily designed to machine low profile materials such as hardwoods, softwoods, fiberboard (MDF), particleboard, plastics and aluminum.

MULTIPURPOSE 42

Moving table, fixed gantry, CNC router primarily designed to machine low profile materials such as hardwoods, softwoods, fiberboard (MDF), particleboard, plastics and aluminum.

Available Table Sizes: Single Table: 10'x5', Dual Tables: 5'x5', 5'x8', 5'x10', 5'x12'

- 12 HP HSD Spindle (3,000-24,000 RPM).

- Fixed Gantry with Moving (front to back) Solid Aluminum Tables

- 4 Position Bar Style Automatic Tool Changer (Standard)

- At the head Automatic Tool Changer (Optional)

- 2nd Head Spindle (Optional)

- 7 Position Bar Style Automatic tool Changer (Optional)

- Pop Up Pins (Optional)

- Automatic Lubrication (Optional)

- Automatic Tool Length Measurement (Optional)

- Three-Dimensional Laser Compensated Axis Alignment

- Control Nesting

- Intelligent Servo Drives Throughout

- Thermwood SuperControl

- Machine Training and Installation

-

13 HP (9 kw) Spindle

A direct driven spindle with a speed range up to 24,000 RPM. The high-frequency spindle is cooled with an electric fan for quieter running and contains ceramic bearings for longer life and for less maintenance. The 13 HP (9kw) spindle provides the user with a heavy duty, precision spindle which provides high performance and reliability. Standard

-

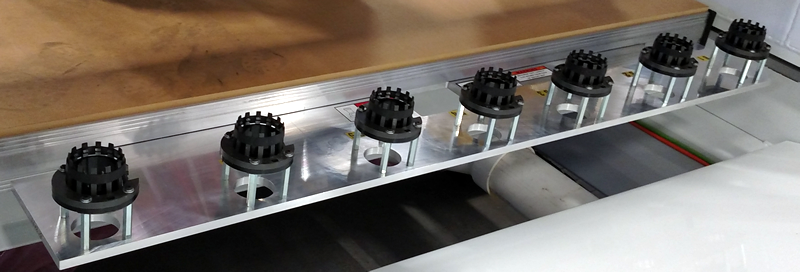

4 Position Bar Style Automatic Tool Changer

Mounts behind the rear of the table and holds the tapered tool holders. When the program calls for a tool change, the head moves back and places the tool into an empty space, it then moves over and picks up the appropriate tool, and then continues the program. Standard

-

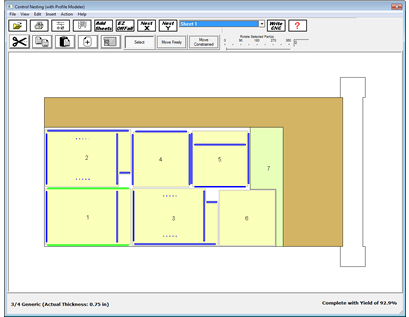

Control Nesting

A user-friendly nesting package integrated into the Thermwood control to nest various parts into sheet stock, thus creating a better yield. Also accepts layered DXF files. Standard

-

Volumetric Laser Compensated Axis Alignment

The machine is calibrated in all axes using a three-dimensional volumetric laser interferometer. This type of calibration is the most sophisticated and most accurate available today resulting in machines that are extremely accurate. Others may use single axis calibration (not nearly as good) and others may not calibrate at all. Uncalibrated machines can generate dimensional errors that can become a real problem. Standard

-

Thermwood SuperControl

The Thermwood SuperControl is a feature rich, high performance CNC control system. Thermwood, the only major CNC router manufacturer that designs and builds its own CNC control, is a leader in implementing advanced control technology. As a result, Thermwood has been granted more patents on CNC router technology than all other CNC router manufactures in the world, combined. Standard

-

Machine Training

We are by your side during your 5 Day training course at our modern, state of the art center (devoted specifically to educating our customers). This is, by far, the fastest and most efficient way to learn. Our machine operator/programmer courses are located adjacent to the machine training lab, where students complete the prescribed projects on a specific training machine utilized only for training purposes. Then, when it comes time for practical applications on a full sized machine, Thermwood's training lab is equipped with a CabinetShop 45 outfitted with all major options and features. Real production-type parts are cut. What a confidence builder! Standard

-

At the Head Automatic Tool Changer

This option consists of tool holder arms and five tool holders, which mount in an arc around the front of the spindle and hold the tapered tool holders. When a program calls for a tool change, the tool is automatically changed at the head. Available for the primary head as well as an optional secondary head. Optional

-

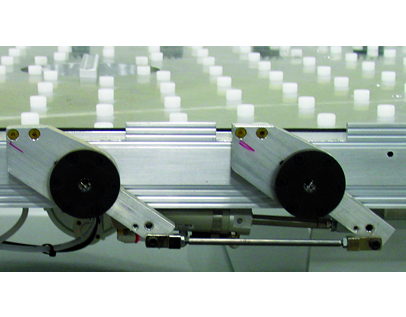

Pop Up Pins

Guides mounted to the table perimeter for locating sheets of material. They are flipped to the up position to locate the material and then retracted to clear during the machining cycle. Optional

-

Automatic Lubrication

Provides positive pressure, air/oil lubrication to the linear trackway bearings and the ball screws This has two major benefits: First, it eliminates the lubrication points which must be servided each shift. Second, it provides positive pressure to the bearing, preventing contamination from entering the bearing. This allows the machine to function in difficult, dusty or hostile environments. Optional

-

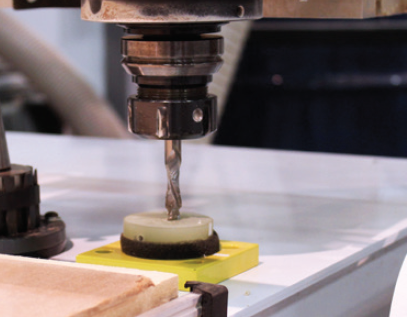

Automatic Tool Length Sensor

Provides an automatic method of measuring tool length and entering tool length offset numbers into the control. This automatically compensates for the new tool length, eliminating the need to precisely locate the cutter bit. It provides a highly accurate method of adjusting tool length for pocketing or profile edges. Optional

-

2nd Head Spindle

A second head can be added to allow simultaneous machining of two parts. The second spindle includes a complete tool slide, second servo-controlled Z-Axis assembly and 24"(600mm) space bar. (Note: Bar Style tool changer cannot be used with this option). At the head Tool Automatic Tool Changer is also available for both heads. Optional

-

Personal Pause Button

Thermwood has developed a remote wireless "Pause Button" which can be clipped to a belt or pocket. Pressing this button stops the machine in place. Optional

-

Vacuum Pump

Universal Vacuum System is a unique method for holding panels to the table top for machining. A sheet of particleboard or low density MDF is used as a work surface on the top fo the table. The high flow pump vacuums through the work surface, holding the part to the table. Pumps are available as 15HP (11kw). Conventional vacuum also available. Optional

-

7 Position Bar Style Automatic Tool Changer

Mounts behind the rear of the table and holds the tapered tool holders. When the program calls for a tool change, the head moves back and places the tool into an empty space, it then moves over and picks up the appropriate tool, and then continues the program. Optional