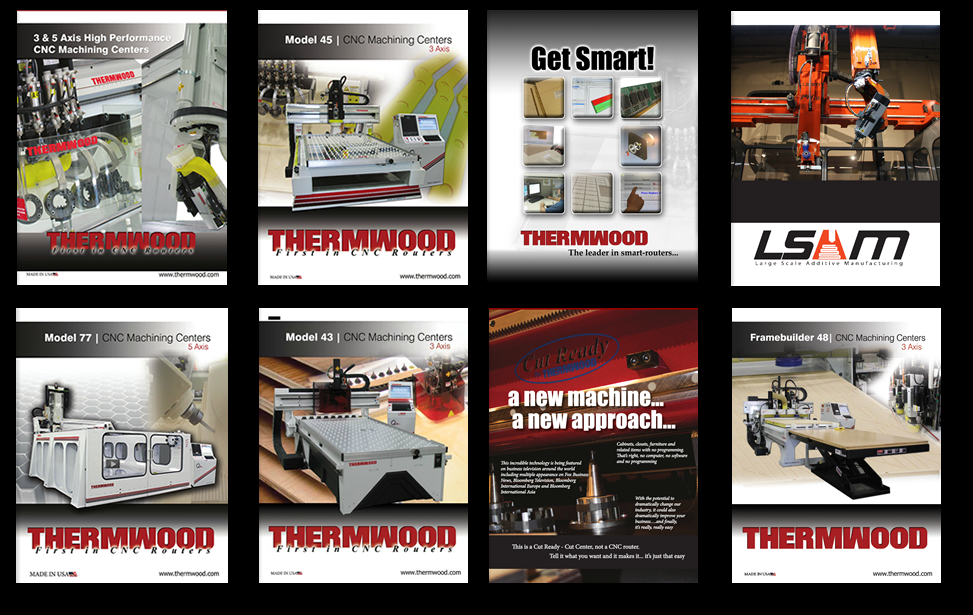

Upholstered Frames Applications

Thermwood offers high-speed machining systems specifically tailored to the manufacture of nested based upholstery frames. These machines feature a unique and highly effective roller hold-down system capable of securely holding course plywood or processing stacked material. Equipped with automatic load/unload systems, Thermwood upholstery machines offer unparalleled performance, throughput and efficiency.

Thermwood CNC routers utilize an advanced next generation CNC control and advanced networked, intelligent servo drives, a combination that offers valuable features, some available only from Thermwood, that have a significant impact on productivity, throughput and profit.

Thermwood machines are rugged engineered structures, designed using the most advanced CAD/CAM and structural analysis. All weldments are fully stress relieved and the final machine is laser calibrated to assure accuracy. Thermwood upholstery machines typically run high-speed production twenty-four hours a day, six or seven days a week.

Thermwood offers total solutions including machines, support equipment, training, software and ongoing service and assistance. Thermwood also offers custom programming and production assistance.

Upholstered Frames Machines