PLASTIC SHEETS - SOLID SURFACE - NON-FERROUS - NESTED BASED - COMPOSITES

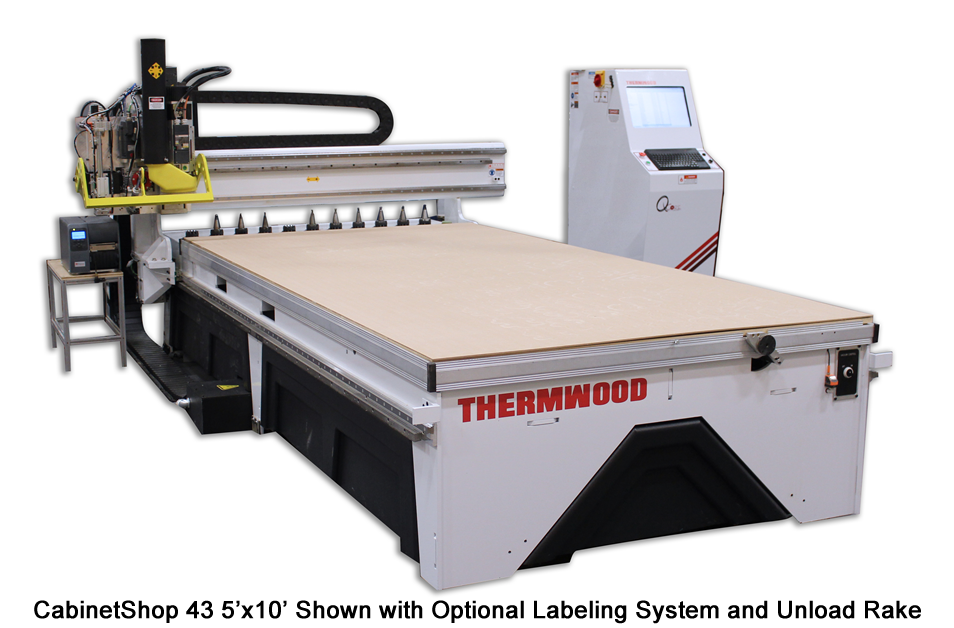

CABINETSHOP 43

High-performance three axis for nested-based custom cabinets, custom furniture, and support products

Solve Your Production Challenges

The CabinetShop 43 is engineered to boost your shop's efficiency, material yield, and overall profitability.

Maximize Material Yield

Our integrated Control Nesting software automatically optimizes every sheet, reducing waste and saving you money on materials.

Increase Throughput

Automated features like the tool changer and unload rake minimize downtime between jobs, allowing you to produce more, faster.

Uncompromising Quality

The robust Thermwood SuperControl ensures smooth, high-speed motion for complex parts without sacrificing precision or quality.

CABINETSHOP 43

High-performance three axis made from fully stress-relieved structured steel for nested-based custom cabinets, custom furniture and support products.

Available Table Sizes: 4'x'8', 5'x10', 5'x12', 5'x20'

5'x10' (with 21 tooling positions and dual pipe dust collection)

Speed: Indexes at 2,800 IPM Standard

Core Performance

- 12 HP HSD Spindle (3,000-24,000 RPM)

- Fixed Steel High Flow Table with Moving Gantry

- Universal Vacuum 1 or 2 Zone(s)

Automation & Efficiency

- 11 Position Bar Style Automatic Tool Changer

- Automatic Tool Length Measurement

- Automatic Programmable Pop-Up Pins

- Control Nesting for Better Yield

Precision & Control

- Three-Dimensional Laser Compensated Axis Alignment

- Intelligent Servo Drives Throughout

- Thermwood SuperControl with Smart Router Technology

Support & Training

- Machine Training and Installation

- Free Lifetime Phone, Forum and Email Support

- Lifetime Machine Support from Thermwood’s Legendary Service and Support

Available Options

- 21 Position Bar Style Automatic Tool Changer

- Unload Rake System

- Full Table Rake w/Integrated Dust Collection (on 43 5'x8' and 5'x10' models)

- Personal Pause Fob

- Pause Mats

- Automatic Labeler

- Customized Accent Colors

- Automatic Lubrication System

CABINETSHOP 43 NESTED BASED WORK CELL PACKAGE:

Complete nested-based CNC routing system with smart-router technology, designed for custom cabinet, closet, and furniture builders. Ideal for producing cabinet and closet boxes, drawer boxes, doors and drawer fronts, and custom moldings.

Available Table Sizes:

5'x10' (with 21 tooling positions and dual pipe dust collectione)

Speed: Indexes at 2,800 IPM Standard

Core Performance

- 12 HP HSD Spindle (3,000-24,000 RPM)

- Fixed Steel High Flow Table with Moving Gantry

- Dual Hi Flow Vacuum Zones

Automation & Efficiency

- Manual Lift System with automatic sequence light sheet locator system

- 21 Position Bar Style Automatic Tool Changer

- Automatic High Tolerance Tool Length Measurement

- Automatic Programmable Pop-Up Pins

- Full Table Off-Load Rake w/Integrated Dust Collection

- Powered Out-Feed Conveyor (61”x144”)

- Remote Fully Functional Operator Station with Monitor and Label Printer

- Personal Pause Fob

- Automatic Lubrication System

- Control Nesting for Better Yield

Precision & Control

- Three-Dimensional Laser Compensated Axis Alignment

- Siemens Intelligent Servo Drives Throughout

- Thermwood SuperControl with Smart Router Technology

Support & Training

- Machine Training and Installation

- Free Lifetime Phone, Forum and Email Support

- Lifetime Machine Support from Thermwood’s Legendary Service and Support