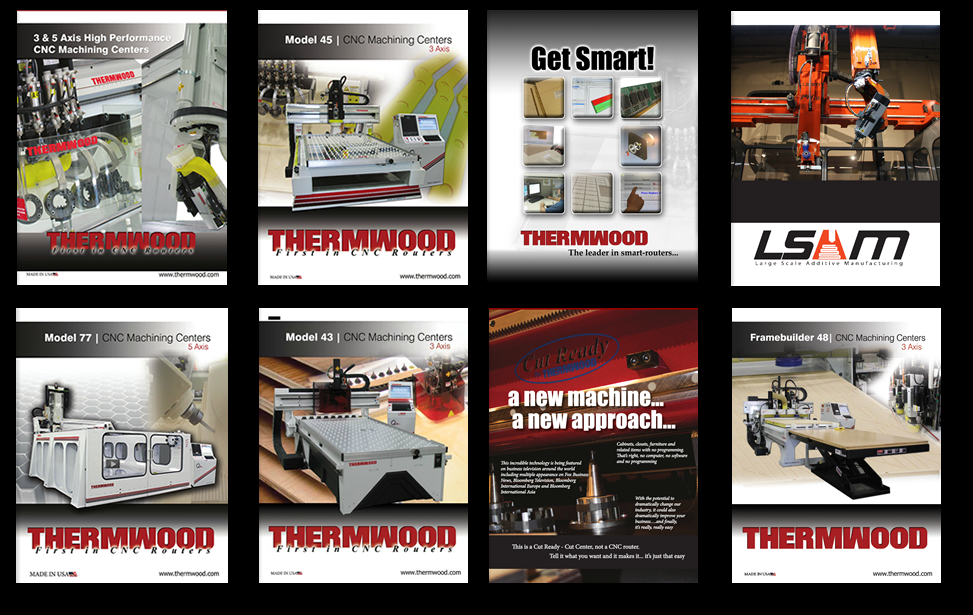

COMPOSITES - AEROSPACE - PLASTIC TRIMMING - NON-FERROUS METALS

MULTIPURPOSE 77

Heavy-duty, high-speed contained system for the machining of large aerospace and composite materials

Fully Enclosed Large Part Machining

The MultiPurpose 77 is a heavy-duty, high-speed 5-axis CNC system in a full enclosure for machining large aerospace and composite parts.

Contained Environment

The full machine enclosure provides dust and debris control, ensuring a cleaner and safer work environment, especially with composites.

Massive Envelope

With table lengths in 10-foot increments, this machine is designed from the ground up for exceptionally large and heavy parts and fixtures.

Aerospace Precision

Features like an impact-resistant head, laser axis compensation, and continuous C-axis rotation are engineered for the tight tolerances of aerospace.

MULTIPURPOSE 77

Heavy-duty, high-speed contained system for the machining of large aerospace and composite materials.

Available Table Sizes: 10'x10', 10'x20', 10'x30', 10'X40' and up in 10' increments in length

Standard Features

- 12 HP 24,000 RPM Router with a 4 Position Automatic Tool Changing System

- Impact Resistant Five Axis Head

- Twelve Position Under Gantry Bar Style Automatic Tool Changer (on 10' wide machines)

- Constant Tip Speed Machining & Tip Center Rotation

- Automatic Tool Length Sensor

- Automatic Lubrication System

- Three-Dimensional Laser Compensated Axis Alignment

- Thermwood SuperControl

Available Options

- 16 or 19 HP Spindle with 4 Position Bar ATC

- Extended Z Axis (up to 60")

- 5 Axis Chip Collection Hood

- Dust Extraction Booth

- Machine Canopy

- Continuous C Axis