Marine/Boat Building Applications

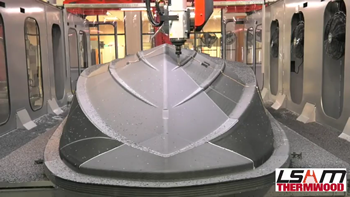

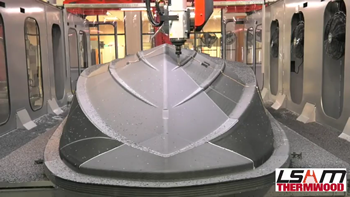

Thermwood offers a variety of machines that are ideal for many aspects of boat and ship manufacturing. Three axis systems machine wood, acrylic and non ferrous metal components. Large table machines are ideal for machining internal bulkheads and structural members. Large envelope five-axis systems up to sixty feet long produce original patterns and molds and are also used to trim major fiberglass and composite components. Significantly larger items are possible by machining in layers. Thermwood’s exclusive volumetric laser compensation results in accuracies that make this approach practical.

Thermwood offers a variety of machines that are ideal for many aspects of boat and ship manufacturing. Three axis systems machine wood, acrylic and non ferrous metal components. Large table machines are ideal for machining internal bulkheads and structural members. Large envelope five-axis systems up to sixty feet long produce original patterns and molds and are also used to trim major fiberglass and composite components. Significantly larger items are possible by machining in layers. Thermwood’s exclusive volumetric laser compensation results in accuracies that make this approach practical.

Thermwood machines use engineered structures designed using the most advanced CAD/CAM and structural analysis. All weldments are fully stress relieved and the final machine is laser calibrated to assure accuracy, including three-dimensional volumetric compensation, a feature not available from other systems in this market.

Thermwood CNC routers utilize an advanced next generation CNC control and advanced networked, intelligent servo drives, a combination that offers valuable features that have a significant impact on productivity, throughput and profit. It can store and seamlessly execute massive CAD generated programs, which are common in this application but can choke lesser systems, making it ideal for this demanding task.

Marine/Boat Building Machines

Thermwood offers a variety of machines that are ideal for many aspects of boat and ship manufacturing. Three axis systems machine wood, acrylic and non ferrous metal components. Large table machines are ideal for machining internal bulkheads and structural members. Large envelope five-axis systems up to sixty feet long produce original patterns and molds and are also used to trim major fiberglass and composite components. Significantly larger items are possible by machining in layers. Thermwood’s exclusive volumetric laser compensation results in accuracies that make this approach practical.

Thermwood offers a variety of machines that are ideal for many aspects of boat and ship manufacturing. Three axis systems machine wood, acrylic and non ferrous metal components. Large table machines are ideal for machining internal bulkheads and structural members. Large envelope five-axis systems up to sixty feet long produce original patterns and molds and are also used to trim major fiberglass and composite components. Significantly larger items are possible by machining in layers. Thermwood’s exclusive volumetric laser compensation results in accuracies that make this approach practical.