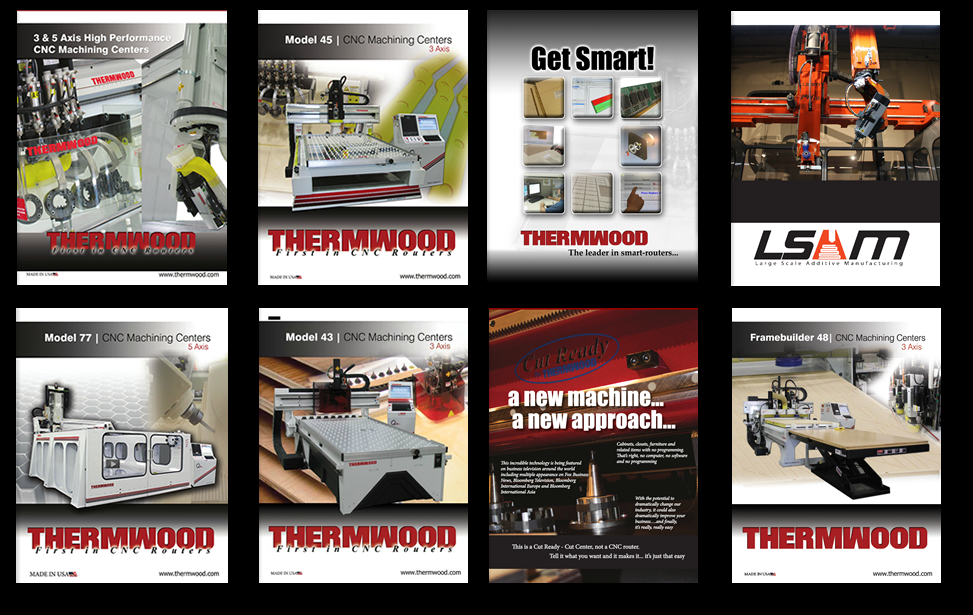

UPHOLSTERED FRAMES - HIGH-THROUGHPUT - MDF - PLYWOOD - NESTED BASED

FRAMEBUILDER 53

Designed for the routing and stack machining of large sheet material such as fiberboard (MDF), particleboard and plywood

Automated Large Sheet Machining

The FrameBuilder 53 is a high-performance system for routing and stack machining large sheets of plywood, MDF, and particleboard.

Stack Machining

A standard roller hold-down system securely clamps stacked sheets, allowing for high-volume production of identical parts in a single run.

Heavy-Duty Power

Comes standard with a powerful 18 HP spindle, ensuring it can handle demanding cuts in tough materials with speed and ease.

Automation Ready

Can be equipped with an optional automatic load/unload system and lift table for continuous, unattended operation and maximum throughput.

FRAMEBUILDER 53

Complete three axis CNC routing system to machine nested upholstered frame parts from sheet stock. The moving gantry, fixed table with roller hold down system is designed for routing and stack machining.

Available Table Sizes: 5'x10', 5'x12', 5'x16', 5'x20'

Standard Features

- 18 HP HSD Spindle (3,000-24,000 RPM)

- Fixed Solid Aluminum Table with Moving Gantry

- Roller Hold Down System

- Three-Dimensional Laser Compensated Axis Alignment

- Control Nesting

- Siemens Intelligent Servo Drives Throughout

- Thermwood SuperControl

- Machine Training and Installation

Available Options

- Automatic Load/Unload System

- Automatic Lubrication

- Automatic Tool Length Measurement

- 2nd Head Spindle

- Pop-Up Pins

- Electric Drill

- Programmable Head Spacing