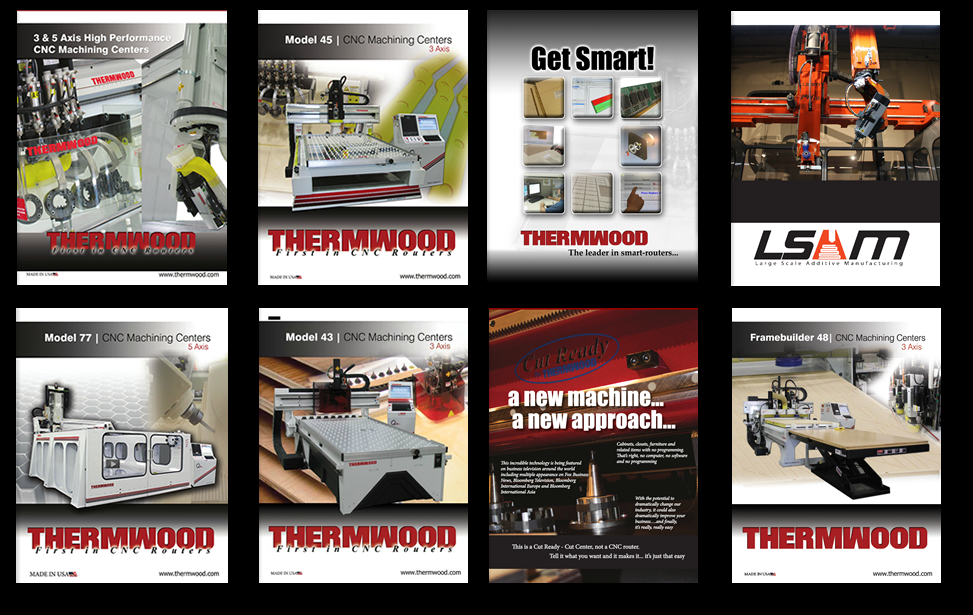

PLASTIC SHEETS - COMPOSITES - NESTED BASED - HIGH VOLUME

MULTIPURPOSE MTR

Complete three axis CNC routing systems with single or dual in-line tables for nested base, composite or plastic sheet material.

High-Production Routing Systems

The MultiPurpose MTR series offers complete CNC routing systems designed for high throughput of sheet materials.

Continuous Production

The dual in-line table configuration (MTR 30DT) allows for loading/unloading one table while the other is in production, virtually eliminating downtime.

Optimized Tooling

Features large-capacity bar-style automatic tool changers to handle a wide variety of tooling for any job, reducing manual changes.

Precision & Reliability

Laser-compensated axis alignment and intelligent servo drives ensure every part is machined with accuracy and consistency.

MULTIPURPOSE MTR

Complete three axis CNC routing systems with single or dual in-line tables for nested base, composite or plastic sheet material.

Available Table Sizes: 5'x10', 5'x12', 7'x12', 7'x20'

Core Features

- 12 HP HSD Spindle (3,000-24,000 RPM)

- Fixed Steel High Flow Table(s) with Moving Gantry

- Available in Single or Dual In-Line Table Configurations

- Large Capacity Bar Style Automatic Tool Changer

- Automatic Tool Length Measurement

- Three-Dimensional Laser Compensated Axis Alignment

- Thermwood SuperControl

Available Options

- 18 HP Spindle

- At the Head Automatic Tool Changer

- 2nd Head Spindle

- Drill Bank

- Aggregate Tooling

- Rotary Playback Device