LSAM - Large Scale Additive Manufacturing

Advanced production systems that create industrial fixtures, molds (including high-temp), tooling, prototypes, and end products from a wide range of materials.

Large industrial “Near Net Shape” additive machines that can print and trim on the same machine.

Thermwood LSAM: A Game-Changer for D-J Engineering

With their Thermwood LSAM MT, D-J Engineering produces complex tooling in weeks instead of months, making the process faster, predictable, and repeatable.

Shaping the Future of Composites Manufacturing

Dr. Byron Pipes and Dr. Eduardo Barocio explain how their Purdue collaboration with Thermwood LSAM is driving large-scale 3D printing and industrial composites innovation.

Revolutionizing Large Scale Manufacturing

LSAM is engineered to dramatically accelerate production, reduce costs, and unlock new possibilities in large-part manufacturing.

Unprecedented Scale

Build massive parts and tools with print beds available up to 40 feet and beyond, enabling manufacturing on a scale previously thought impossible.

Two Processes, One Machine

Go from a printed near-net-shape part to a final, trimmed, high-precision product on a single machine, streamlining your workflow.

High-Temp Polymers

Process virtually any composite thermoplastic, with temperatures up to 450°C to produce strong, durable, and reliable parts for demanding applications.

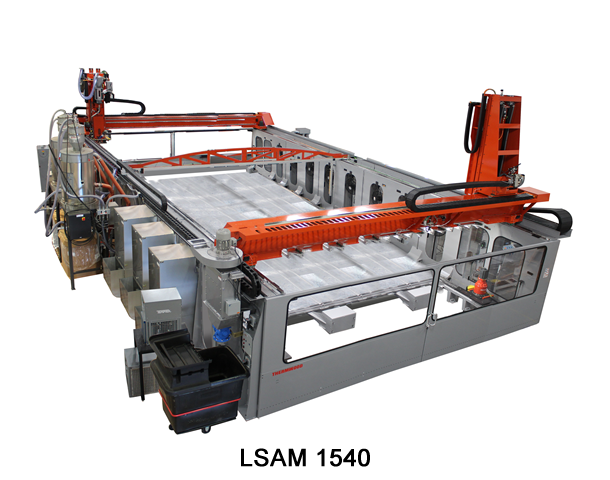

Standard LSAM Flagship (Closed Configuration)

These are near net shape additive manufacturing systems that offer both print and trim on the same machine. They are configured with a fixed table, high walls, and a moving gantry or gantries, and can be fully enclosed to meet CE requirements.

Available Sizes: 10'x10', 10'x20', 10'x40', 15'x20', 15'x40'

The model numbers (1010, 1020, etc.) denote the table size in feet. While 40-foot lengths are common, even longer machines are possible.

Gantry & Control System

- Models 1010, 1020, 1040,1520, 1540: Dual gantries and dual controls, one for printing and one for trimming. This allows simultaneous printing on one end of the table while trimming on the other.

Advanced Capabilities

- LSAM Flagship models can be equipped with a VLP System.(This system enables printing parts as tall as the machine table is long on a moving vertical table.)

- Machines 1010 and larger can be equipped with a Angle Layer Print System.(This system enables printing parts at a 45° angle.)

LSAM MT (Open Configuration)

This machine is configured with both a print and trim head on a single fixed gantry mounted over either a 10'x5' or 10'x10' moving table. This system can both print and trim, but not at the same time. The open configuration cannot be built to meet CE requirements.

Key Features

- Features either a 10'x5' or 10'x10' primary working area (max vertical build of 5').

- An additional two feet of table length accommodates an optional Vertical Layer Print Table, allowing parts up to ten feet tall to be printed vertically.

- Utilizes the same powerful print and trim heads as all other LSAM machines.

- Also available as an optional "Print Only" machine for those with existing trimming capabilities.

Advanced Capabilities

- LSAM MT 1010 can be equipped with a VLP System.(This system enables printing parts as tall as the machine table is long on a moving vertical table.)

- LSAM MT 1010 can be equipped with a Angle Layer Print System.(This system enables printing parts at a 45° angle.)

LSAM Additive Printers

"Print Only" systems built around Thermwood's 40mm LSAM print head, offering highly capable machines at an attractive price point. These systems feature a single gantry, moving table configuration.

Available Table Sizes: 5'x5', 5'x10' or 10'x5'

Configurations & Capacity

- The 5'x10' table is available as 5' wide with 10' motion or 10' wide with 5' motion.

- Standard single servo table drive accommodates parts up to 1,000 lbs.

- An optional second table drive increases max weight capacity to 2,000 lbs (10' wide table only).

- The 5' wide by 10' deep version supports Vertical Layer Printing for parts up to 10 feet tall.

Core Technology

- Uses the exact same print head and advanced Ultra 6 control as the largest LSAM systems.

- A rigid, structural steel gantry incorporates a fume extraction system with activated charcoal filters.

- Standard single hopper polymer dryer; dual hopper dryer available as an option.

- A full machine enclosure is available, allowing the machine to meet European CE standards.

Advanced Capabilities

- LSAM AP 510 can be equipped with a VLP System.(This system enables printing parts as tall as the machine table is long on a moving vertical table.)

What is LSAM?

LSAM (pronounced L-Sam) represents the industry-leading technology for large scale 3D printing of thermoplastic polymers. It utilizes unique patented technology to produce the highest quality printed structures available.

LSAM uses the "Near Net Shape" approach to part production where the part is first printed at high speed slightly larger than needed, then trimmed to the final size and shape. This is the fastest, most efficient method of 3D printing large structures. With LSAM, both printing and trimming can be done on the same machine.

LSAM can process parts from virtually any thermoplastic composite material including high temperature materials that are ideal for molds and tooling. Its unique printing system produces parts that are solid, fully fused, vacuum tight and virtually void free, making it a full-fledged industrial additive manufacturing system intended for serious production.

The LSAM Difference

The LSAM Print Process

LSAM prints a large bead at room temperature in a process which is an exercise in controlled cooling. A patented compression wheel totally fuses layers together, creating solid, virtually void-free structures that can sustain vacuum in an autoclave without add-on coatings.

- Patented "Bead Board" virtually eliminates warping.

- Compression wheel ensures superior layer fusion.

- Precise bead dimensions measured in thousandths of an inch.

Robust Industrial Machine Design

LSAM machines are large, robust industrial structures built from fully annealed steel plate using slot-and-tab construction. This results in an order of magnitude higher strength and stiffness than typical machine construction. The entire machine is volumetrically compensated for superior accuracy.

- Dual gantries for simultaneous printing and trimming.

- Laser-aligned and compensated on all axes.

- Configurations available up to 100 feet in length.

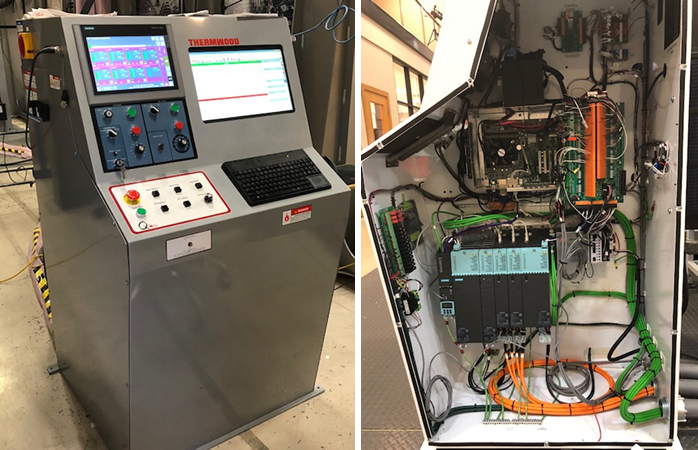

The Thermwood SuperControl

The LSAM control provides unique functions to make the print process easier and more capable. It automatically synchronizes the melt pump output to machine speed for perfect bead dimensions, and orients the compression wheel to the direction of motion, eliminating the need for complex programming.

- Fully integrated temperature and pressure controls.

- Automatic layer time control for consistent prints.

- Simple, one-button operation for complex functions.

Industry-Leading Slicing Software

To address the lack of professional software for "Near Net Shape" printing, Thermwood developed a true CAD slicing software that works within Mastercam. It accepts geometry in every major CAD format and offers powerful, feature-rich programming capabilities.

- Automatically adjusts for unique machine print characteristics.

- Allows solid or sparse infill, variable boundary layers, and more.

- Programs incredibly complex parts by printing concurrent structures.